Lexus Imaginative Thinking Produces Fourth Generation Self-Charging Hybrid Powertrain for the New UX Compact Crossover

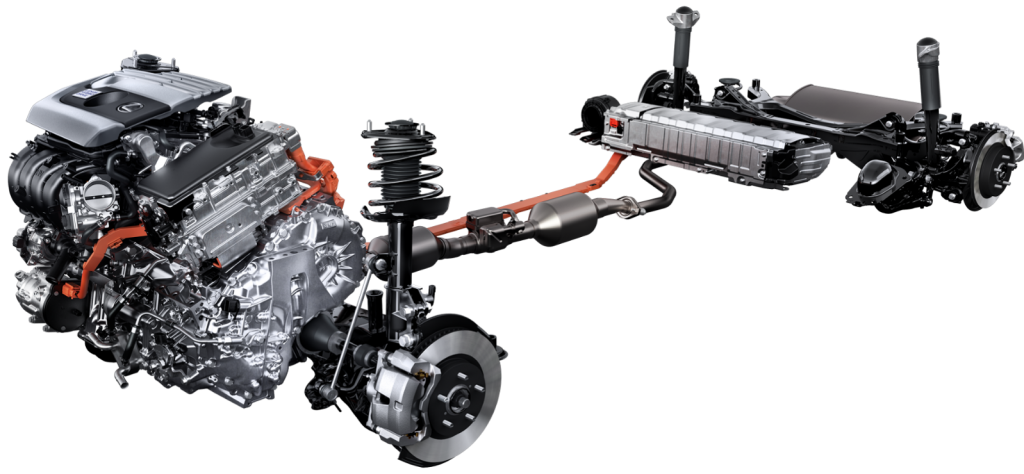

The new UX 250h luxury compact crossover is the result of a five-year development programme that involved hundreds of engineers and technicians in creating one of the most advanced vehicles Lexus has ever built. Their ground-breaking work included delivering a new, fourth generation self-charging hybrid powertrain, each element of which benefits from innovations and improvements in design and performance.

2.0-litre petrol engine

The 2.0-litre in-line four-cylinder engine is one of the most efficient Lexus has built, achieving 41 per cent thermal efficiency. Its advanced features include laser-cut intake valve seats and D4-S fuel injection which combines both direct and secondary port injectors. A high, 14:1 compression ratio supports overall efficiency, while an exhaust heat recirculation system helps the engine warm up quickly. The unit is equipped with electric intelligent variable valve-timing (VVT-iE) which enhances driveability while at the same time reducing emissions.

Hybrid transaxle

A new front hybrid transaxle connects the engine to two electric motor/generators (MG1 and MG2). To make it more compact and to improve driving performance, an innovative multi-axial layout was devised, replacing the previous arrangement in which the motors were located on a single axle. The transaxle’s length has been reduced by about 45mm, giving the steering gear more room to deliver a class-leading turning diameter (10.4m kerb-to-kerb). With overall transaxle losses reduced by a quarter, the MG2 is now a higher-speed motor, yielding better performance and efficiency.

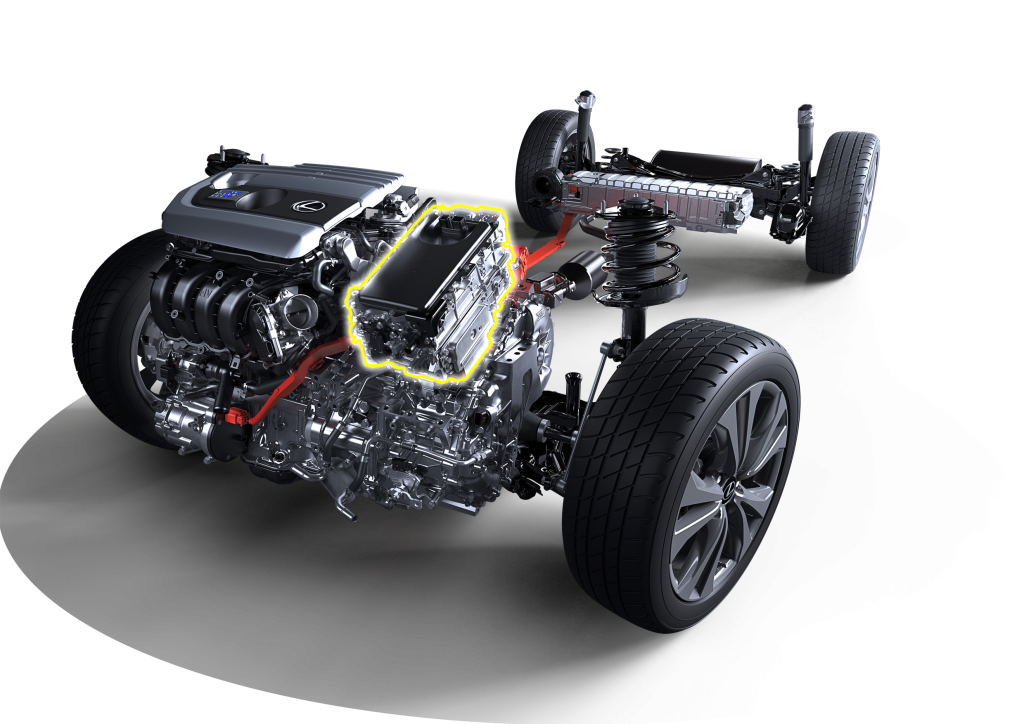

Power control unit

The new power control unit (PCU) is 20 per cent more powerful yet 10 per cent lighter than the previous version. Size and weight, critical for both design and safety considerations, were reduced by developing a new, compact circuit board, DC-DC converter and power stack structure. Together these reduced power losses by 20 per cent and improved fuel efficiency. Lexus engineers also introduced a two-in-one power card that is smaller and has double-sided cooling efficiency. Furthermore, optimisation of the output filter has reduced noise levels.

The PCU is mounted directly above the front hybrid transaxle, which contributes to the compact size and reduced weight of the entire system and helps free up more space inside the engine compartment. This in turn allows for a low, aerodynamic bonnet and better protection for pedestrians in the event of a collision.

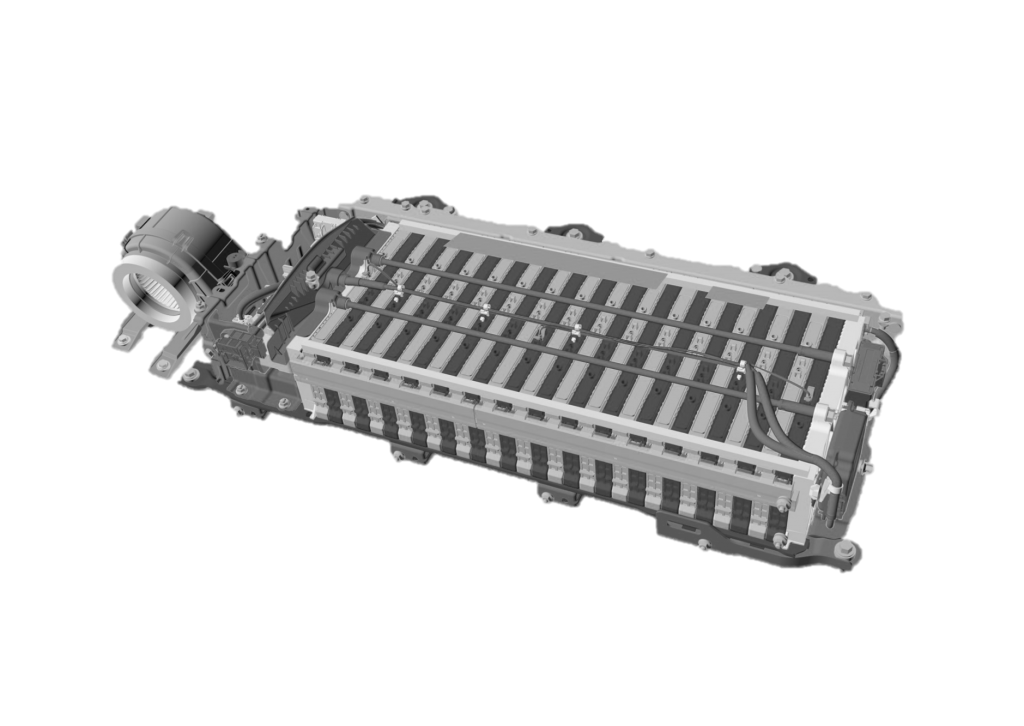

Hybrid battery

The UX 250h’s new nickel-metal hydride (NiMH) battery not only makes for better fuel efficiency and EV (electric vehicle) performance, it also takes up less space. Its smaller size has been made possible by a revised construction and more compact cooling system. It also benefits from a new electrode material. The battery comprises 180 1.2V cells, giving a total voltage of 216V and output of 24kW. It is located beneath the UX’s rear seat, minimising intrusion in the load space and contributing to the car’s optimised front/rear weight distribution and low centre of gravity.

E-Four all-wheel drive

The new E-Four all-wheel drive system available on the new UX 250h uses a dedicated electric motor/generator integrated in the rear differential. Compared to previous Lexus E-Four systems, the rear hybrid transaxle has been significantly reduced in size and weight, which improves both luggage space and the car’s handling stability. The system uses sensors to monitor wheel speed, G-forces, yaw rate, steering angle and other factors, applying the data gathered to precisely control front-rear torque distribution when accelerating, cornering or driving on slippery surfaces. The front/rear drive torque split can vary from 100:0 to 20:80. E-four also ensures stable driving on uphill slopes or snow-covered roads, while fuel consumption is lower in comparison to vehicles equipped with conventional, heavier all-wheel drive systems.

Lightweight materials

The engineering team sought to reduce weight wherever possible to improve the UX 250h’s efficiency and performance. The engine is one of the lightest in its class, weighing 112kg, but a further 27kg were saved by using aluminium in place of steel for the vehicle’s doors, wings and bonnet, and composite material for the tailgate. The use of an aluminium internal tailgate frame with outer and inner panels made of Super Olefin Polymer is a Lexus first.

These weight-saving measures result in the UX having the lowest centre of gravity of any vehicle in its class and the kind of agile handling normally associated with a hatchback.

The new Lexus UX is available to order now, with first deliveries to UK customers from March this year.

ENDS